Alumina Hopper

Crust Breaker

Alumina Feeder

Anode Cover

Top Crust

Cryolite Electrolyte

Aluminum Metal Pad

Please hit a button

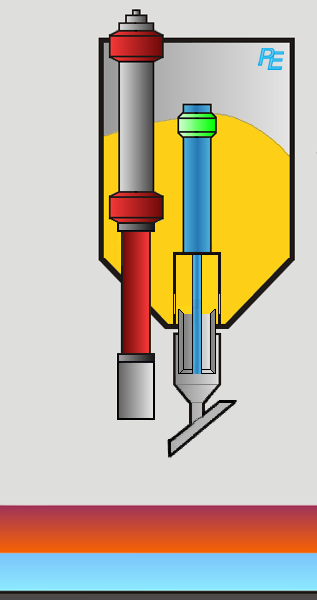

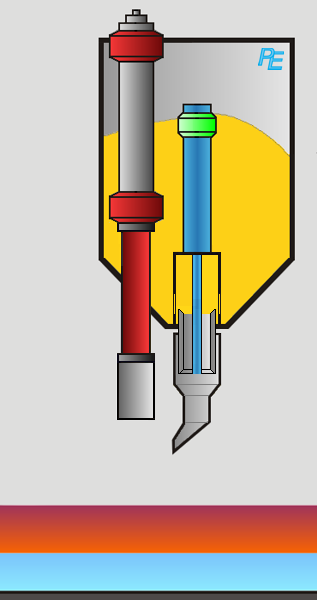

Crust

Breaker

Pechiney

Feeder

Alcoa

Feeder

Feeding Parameter

The Hall - Heroult Process

The conventional Hall - Héroult process produduces aluminum by high temperature smelting. Alumina (an oxide of aluminum Al203) is dissolved in molten cryolite (Na3AlF6). The electrolytic process decomposes the oxide between carbon and aluminum electrodes at about 950 °C to aluminum and oxygen. The electrolytic process consumes alumina i.e alumina must be added to the elctrolyte to keep its concentration constant.

Alumina Feeding

Two devices execute the aluminum feeding task: first the crust breaker opens a hole in the top crust. The top crust is a layer of solidified electrolyte on top of the electrolyte. Then the alumina feeder drops a defined amount of alumina into the elctrolyte. The process computer controls the actions of both devices.

Visualization of the Feeding Process

You may activate the crust braker or alumina feeder by clicking on the corresponding button or on the device itself.

You find more information how to use this web page on the corresponding User's Guide webpages. The Theory web pages discuss the theoretical background of alumina feeding.

close

09Okt16 15H00